RBWE Faster Blaster

RBWE Faster Blaster Specification

- Industries

- Oil And Gas

- Air Gases

- Nitrogen

- Noble Gases

- Argon

- Application

- Industrial

About RBWE Faster Blaster

Our company is one of the fastest growing entity to manufacture and supply a wide assortment of RBWE Faster Blaster this systems are the favored strategy for surface readiness utilized by expert temporary workers and prescribed by covering makers for an extensive variety of applications We are offering services like concrete repair and restoration flooring painting coating general construction airports bridges highways remediation utility marine or shipyards demolition renovation storage tank maintenance and so many others The offered RBWE Faster Blaster surface arrangement advancements and aptitude than some other producer and become prominent driving entity in the the world as surface readiness innovationFeatures

RBWE items are earth well disposed and give the most financial answers for your surface readiness ventures

Our frameworks accommodate lessened poisons at the occupation site diminished clamor and consider numerous undertakings to happen in the meantime

The RBWE vertical shot impacting frameworks are utilized to set up the sides of petrochemical or water stockpiling tanks deliver structures and other vertical or close vertical steel surfaces

These proficient frameworks are utilized as a part of conjunction with rooftop fixing frameworks pressure driven winches or cranes to set up the sides of vertical steel surfaces

The extraordinary frameworks work in an all over course to clean and profile the surface

They are guided through remote control for included profitability

RBWE steel shot impacting is a work and efficient process that strips cleans and profiles all the while

It leaves the surface quickly prepared for the utilization of coatings or overlays wiping out drying time and expensive transfer methodology connected with other surface readiness techniques

The vertical RBWE steel shot impacting frameworks use persistent inside reusing of grating that dispenses with pollution for the most part connected with outdoors impact frameworks

A scope of surface profiles can be accomplished through choice of steel shot or precise steel grating by sort size and machine travel speed

Vertical systems used in conjunction with especially developed rigging or special hydraulic winch systems can prepare the sides of steel storage tanks internal as well as external ship hulls and other vertical steel surfaces with greater efficiency that other methods

We provide high quality RBWE Shot Blasting Machines Leveraging our technical expertise

We prepare these with the combination of the flat suction seal and the vacuum from the HIVAC dust collector

This arrangement keeps the machine tight against the wall and confirms a dust free blast

We have carefully designed these to ensure low maintenance cost

These are highly appreciated for various effective industrial applications like shipping and offshore industries

The highgrade aluminum construction makes the unit very light and the same time robust

Two versions of this machine are available to suit most budgets oneapplication requirements

Advantages

Advantages to using a RBWE system for steel surface preparation over other methods

Accomplish high profitability rates up to 6 times more prominent

Requires less labor and minimizes administrator weakness

Reuses abrasiveleads to potential cost reserve funds

Streamlined taking care of and transfer of squanders

Ecologically neighborly no requirement for control

Permits different exchanges to work all the while

No exorbitant pumps to purchase or keep up

No blaze rustingshot impacted surface is spotless and dry

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

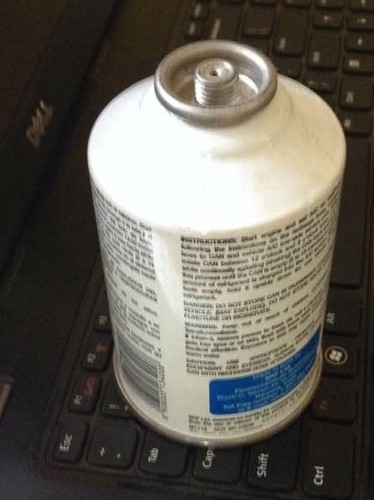

More Products in Refrigerant Gases Category

R134A Refrigerant Gas

Minimum Order Quantity : 2 Pieces

Noble Gases : Argon

Application : Industrial

Air Gases : Nitrogen

Industries : Oil And Gas

Elemental Gases : Hydrogen

R22 Refrigerant Gases

Minimum Order Quantity : 1 Piece

Noble Gases : Argon

Application : Industrial

Air Gases : Oxygen

Elemental Gases : Hydrogen

Refrigerant Gas

Minimum Order Quantity : 2 Cubic Meters

Noble Gases : Argon

Application : Industrial

Air Gases : Nitrogen

Industries : Oil And Gas

Elemental Gases : Hydrogen

R32 Refrigerant gas

Noble Gases : Argon

Application : Industrial

Air Gases : Nitrogen

Industries : Oil And Gas

Elemental Gases : Hydrogen